|

Serving

the Aggregate, Chemical Limestone and Chemical Lime Industries |

Recent

additions to the DCA group has enhanced its ability to offer

expanded services in

the areas of geology, industrial minerals, marketing, market

research, strategic planning, business development, and certified

industrial plant and equipment appraisals.

DCA handles engineering and

consulting assignments in many facets of the aggregates, sand &

gravel/mining and processing, chemical

lime and limestone industries.

Our Services include design and

implementation of core drilling programs including logging cores

and determining quantity and value of reserves.

-

Open Pit Mine Engineering/Planning

-

Open Pit and Underground Mine

Design

-

Reserve Analysis and

Evaluation

-

Geological Services and

Evaluation

-

Underground Feasibility

Studies

-

Ventilation and Rock

Mechanics

-

Production Performance

Evaluation

-

Transition from Open Pit to

Underground

-

Certified Plant and Equipment

Appraisals

-

Certified

Industrial Property Appraisals

-

Technical Equipment

Evaluation

-

Plant Feasibility Studies

-

Cost Reduction Evaluation

-

Engineering Services

-

Blast Design and Fragmentation

Evaluation

-

Quarry & Plant Permitting

-

Plant Engineering / Layout

-

Market Analysis and Development

-

Business Development & Strategic Planning

-

Acquisition / Merger / Sale Assistance

-

Hydrator And Baghouse Engineering Design

-

Expert Witness

Click

Button To See Some of DCA'S

Completed Projects

And

Recently Added Services

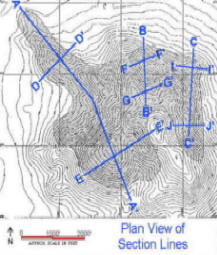

Mine

Design and Planning

The company

provides engineering, mine design, and mine planning for the following types of operations:

-

Surface quarrying operations

– an evaluation of the reserves, structural geology and rock

type is made from on-site visits and drilling information. Slope

stability analysis is completed with haulage studies and a

review of blasting practices.

-

The quarry plan is then

designed to maximize recovery and minimize operating costs.

Underground operations – current underground mines are evaluated

for efficiency of haulage, drilling/blasting, ventilation,

dewatering systems and evaluation of current roof control plan

and pillar designs.

|

Trouble-shooting services are provided to evaluate the

reason for slope failures and corrective measures are

provided. Review of roof and pillar problems are

completed with recommendations and provisions to

eliminate the effects of “bad ground” in the future. |

|